29 Jan 2016 - The Maiden Flight of the MAX

The first flight of the 737 MAX took place at 9:48 am (17:48 GMT) on 29th Jan 2016 from Runway 34 at Renton Municipal Airport. At the controls were Capt Ed Wilson, chief pilot 737 Program, and Craig Bomben, vice president of flight testing. Bomben said that "other then deteriorating weather at Renton, we had no butterflies or jitters in our stomachs. We did get out of Renton in the nick of time."

The departure time was brought forward slightly due to worsening weather conditions. Probably much to the relief of the 4,000 Boeing employees, media members and invitees who attended the event.

The aircraft, registration N8701Q (MSN 42554, /LN 5602), named Spirit of Renton, flew for 2 hrs 47 mins mostly to the East of Seattle using callsign BOE1, It landed at Boeing Field runway 13 at 12:35pm. The aircraft stayed below 250 knots for the whole flight, which is normal on first flights. It initially climbed to 15,000 feet, and later climbed to 25,000 feet. Unusually for a first flight, the landing gear was retracted. This was achievable because of the maturity of the basic platform.

Plot of the first flight from Flight Radar 24

Ed Wilson said after the flight. "We were amazed at how quiet the cabin was, I took a walk mid-flight through the cabin and was impressed.". He went on to say “It flew beautifully, we had no issues.”

(Photo Guy Norris)

Test pilots Craig Bomben (left) and Ed Wilson (right) emerge from IA001 to be greeted by Boeing Commercial Airplanes president Ray Conner.

The second MAX aircraft built will be incorporated into the test program within a month. The third and fourth MAX's are in varying stages of completion on Renton's "Go Slow" Surge Final Assembly Line. According to Boeing's chief project engineer Michael Teal, the aircraft's test fleet will wrap up the campaign by the end of the year. After type certification, the aircraft will go to launch customer Southwest Airlines.

Boeing’s test pilots said they plan nine months of aerial tests for the Max, but have given themselves 20 months, the same as the 787, despite that plane’s bigger technological leap. “I don’t want to cut [the allotted testing time to the bone and have to add days on to the end, and unfortunately we have done that in the past,” said Keith Leverkuhn, Boeing’s program manager for the 737 Max.

The flight test fleet is as follows:

1A001, FF 29 Jan 16, Boeing livery, N8701Q, MSN 42554, LN 5602, MAX-8

It performing stability and control test amongst other things, which finished in July 2016.

The aircraft, which returned to Seattle on June 28 2016 from California, where it underwent runway performance work at Edwards AFB, Its flight tests had finished by Autumn 2016

The interior of the first 737 MAX test aircraft 1A001, Photo Boeing

1A002, FF 4 Mar 2016, “light” livery, N8702L, MSN 36989, LN 5668, MAX-8

This aircraft was mostly used for propulsion tests associated with the MAX’s CFM Leap 1B engine

This aircrafts program started with nautical air fuel mileage tests.

It then went onto high and low altitude testing. The low-altitude tests on the begin on 17 April 2016. The tests required a minimum 80-degree F temperature and were flown at at 1,500 feet between Sarasota-Bradenton International Airport and the Gulf,with the landing gear down throughout the test flights. From 2 May 2016 high altitude testing began at La Paz, Bolivia. The airport’s 13,300-ft. (4,050-m) altitude tested the MAX’s capability to take off and land at high altitudes, which can affect overall airplane performance.

The aircraft was also used to complete the flight-loads survey. Only the outboard wing was surveyed for flight-loads because of the winglet change, “Results were as expected. In fact, there’s been no drama, and testing went very well.”

In June 2016 the engine instrumentation for thrust-versus-drag calculations and schedules was removed.

The aircraft’s next exercise was community noise testing at Glasgow, Montana.

Water spray testing at Glasgow, Montana to test the resilience of the engines and APU to withstand water ingestion sprayed up from the landing gear or reverse thrust. A great video of this test in progress is available here: https://youtu.be/hEx7Glp8Kk0

Photo Boeing

1A003, FF 14 Apr 2016, “light” livery, N8703J, MSN 42556, LN 5728, MAX-8

Was used for:

- systems and propulsion certification tests

- validation of the 737’s new fly-by-wire spoilers

- evaluation of the Leap 1B integrated drive generator

- the autoland and head-up display systems

- engine drainage tests

1A004. FF 7 May 2016, Boeing livery, N8704Q, MSN 36988, LN 5788, MAX-8

This aircraft was configured with a virtually complete passenger interior in the style of Southwest. However, some instruments remain in the aft of the cabin for environmental tests, such as smoke-penetration and including smoke and Halon detection.

The Cabin of 1A004 has a passenger interior with some flight test equipment at the rear Photo: Chris Sloan

Program Manager Mike Teal said: “In our Right at First Flight initiative, we’re working on what we call ‘fly like the airlines.’ In two days, we did eight simulated flights. We’d fly for an hour and a half, we’d land, and then we’d pretend we taxied in and then we would do all the ground checks, we’d turn the engines off, we’d fuel it, we’d do any maintenance an airline would typically do on the ground during a thirty minute turn, then we’d start the engines and take back off.”. Boeing intended to effectively de-bug the airplane with the exercise, explained Teal, thereby ensuring the airplane is customer-ready upon delivery. “That testing was very successful,” he said. “We did find a couple of, I’ll call them squawks, but that’s what you want to find and it turned out that the two that we found we already had on our list of things we had to fix.” Most of the testing is for certification, but this is aimed at making the aircraft customer-ready.

ETOPS testing and Farnborough airshow appearance.

SROV (Service Ready Operational Validation) route proving trails commenced 19 September 2016 This was done with launch customer Southwest Airlines, using the fourth prototype over a six day period. SROV uses several airports in Southwest’s route network to simulate the kind of real life things the airplane will encounter on any given day of revenue service. Southwest and Boeing pilots will fly routes from Love Field in Dallas to cities including Albuquerque, Denver, Chicago, Austin and Phoenix. Southwest’s maintenance and ground crews at each airport will get hands-on experience, doing everything from towing and fuelling the airplane, to conducting fit checks of ground support equipment and performing maintenance.

After customer testing the last tests are the functionality and reliability testing in autumn.

Environmental testing:

- Cold weather testing in Yakutsk, Russia from 13 Jan 2017 for 3 days.

- Hot weather testing in Darwin Australia from 26 Jan 2017.

Boeing spokesman Ken Morton said it was part of its certification process. The aircraft has to be subjected to a hot soak and a cold soak,” he said. “This involves going to a very cold place and a very hot place. The aircraft is left sitting on the ground for a certain period of time, and then the crew go back on board and make sure everything runs as it should do.”

Endurance testing. Including, on 11 Feb 2017, skywriting! For eight of its 9h 11mins aloft, the 737 MAX worked on its aerial penmanship writing a 997 km (619 mi) long, 277 km (172 mi) high ‘MAX’ over the states of Washington and Montana.

Graphic from Flightradar24.

1D001. FF 13 Apr 2017, Boeing livery, N7379E, MSN 42987, LN 6250, MAX-9

The first of two MAX-9 flight test aircraft due to participate in an 8 month flight test program. About 30% of the test points completed by the 737 Max 8 must be revisited during the campaign for the 737 Max 9, said chief project engineer Michael Teal. All of the testing is focused on how the larger size of the 737 Max 9 affects the aerodynamic characteristics and the environmental control system.

The take-off of the first flight was delayed by 90min at Renton due to a loss of telemetry communications between the aircraft on the ground with Boeing's control centre. A radio dedicated to flight test communications also failed to work properly after take-off. Despite the difficulties, Boeing Test & Evaluation engineering test pilot Christine Walsh (in command) and Chief model pilot test Ed Wilson (RHS) managed to complete a full test card,

The aircraft initially climbed to 10,000 ft. where the crew cycled the landing gear before slowly climbing to 12,000ft. Following initial handling and flying qualities tests at these lower altitudes the crew headed to Eastern Washington, reaching a maximum altitude of 24,000ft. and top speed of 240kt. before descending to 15,000ft. and slowing for most of the remainder of the sortie. The crew also shut down and relit both Leap-1B engines which are rated at 28,000 lb. thrust for the larger 737-9. A higher thrust "bump rating" is also in development by CFM, though the final thrust level option for the -9 is still to-be-determined.

The flight, concluded with a landing in a gusty 20kt crosswind at Boeing Field, Seattle, at 1:34 pm PT. “It was quite a work out,” says Walsh who adds that the aircraft flew through moderate turbulence on its final approach to Seattle. The flight also evaluated several new systems on the MAX, including the fly-by-wire spoilers. “We were able to see the operation of the landing attitude modifier (LAM) system with the flaps at 40 deg.“ says Walsh, referring to the operation of the spoilers at 30 or 40 deg. At these flap setting the spoilers partially activate to reduce lift which requires angle-of-attack to be increased. This raises the nose to increase nose gear contact margin.

Walsh said. The crew also shutdown and re-lit each of the 28,000lb-thrust CFM International Leap-1B engines in sequence. The 737 Max 9 landed around 1:40pm with only one uncompleted task: a publicity photo by the chase aircraft, which was called off because of a thick blanket of clouds around Mount Rainier.

First flight of the 737 MAX-9, 10:52am PT, 13 Apr 2017. Boeing Test & Evaluation engineering test pilot Christine Walsh (in command) and Chief model pilot test Ed Wilson (RHS) from Renton to Boeing Field. The flight lasted 2 hours 42 minutes.

Following the initial handling tests, Boeing continued opening up the MAX-9 flight envelope later in April as it moved into initial airworthiness and flutter testing. Stability and control work were conducted along with runway tests, the latter involving a deployment to Southern California.

Flight tests with 1D001, the most significantly instrumented of the two MAX-9 aircraft, replicated those of the -8 with additional emphasis on potential differences in the stability and control of the stretch version.

Testing through the second half of 2017 focused on areas such as "performance, stability control and autoland – those things associated with the longer body of the Max 9", said Keith Leverkuhn. Flight-testing finished at the end of 2017, with certification on 16 Feb 2018 and the first delivery on 21 March 2018.

1D002. FF May 2017, Lion Air livery, N739EX, MSN 42989, LN 6308, MAX-9

The second 737-9 test aircraft first flight was in May 2017. Painted in the colors of Lion Air, the Indonesia-based LCC that launched the model with an order for 201 in February 2012, the second aircraft had a light instrumentation suite similar to that installed on 1A004, the fourth 737-8 certification aircraft which was used primarily for functionality and reliability testing. 1D002 was assigned to environment control system testing.

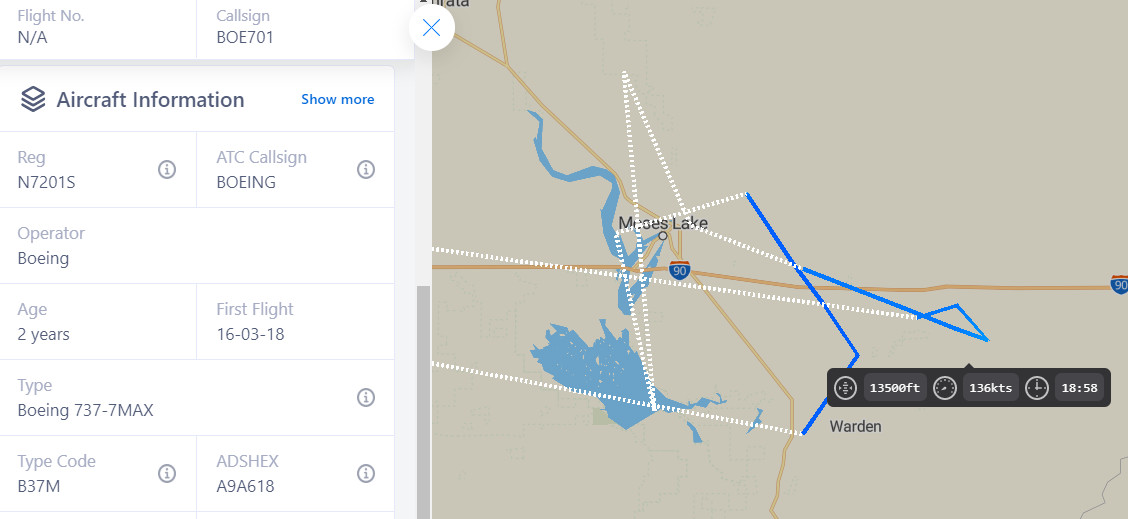

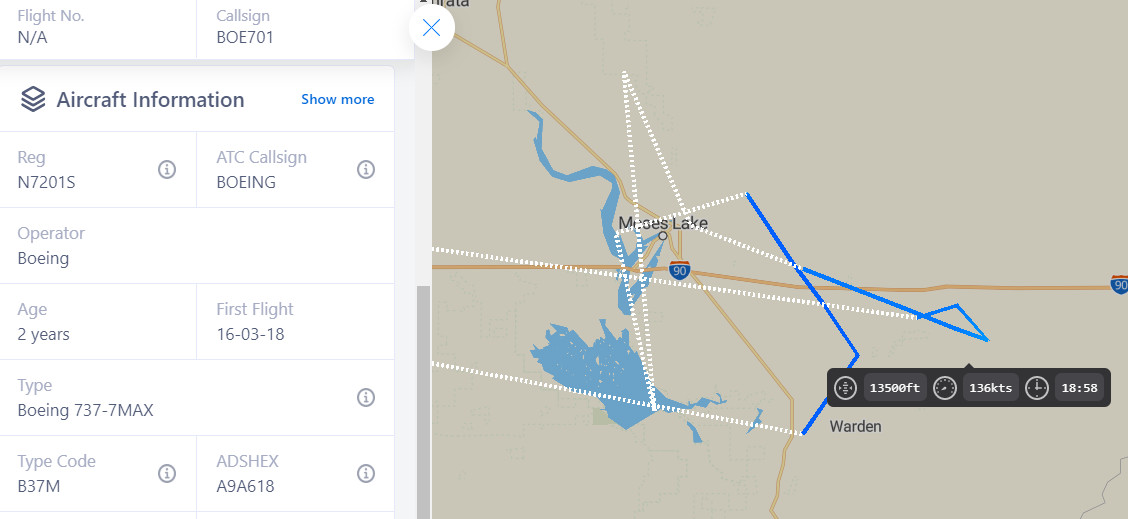

1E001. FF 13 Mar 2018, Boeing livery, N7201S, MSN 42561, LN 6744, MAX-7

1E002. FF April 2018, Boeing livery, N7202U, MSN 42569, LN 6798, MAX-7

The first flight of the MAX 7 was on 16 March 2018. It was flown by Boeing Test and Evaluation captains Jim Webb and Keith Otsuka from Renton to Boeing Field. The aircraft departed at 10:17am PST and climbed to 25,000ft at 250kts. east to pass over the Olympic Peninsula before flying back over Seattle on its way to eastern Washington. The crew continued to conduct handling tests while descending to 15,000 ft. before flying a missed approach to Boeing’s Moses Lake test site. The aircraft was then flown to the Mount Rainier area, where Boeing took the opportunity to capture some air-to-air photographs before landing at Boeing Field. The flight lasted 3 hours and 10 mins. 1E001 was placed into storage from June 2023 until October 2025 while an engine anti-ice redesign was made.

This aircraft was used for the FAA post-MCAS modifications, recertification flight test program from 29 June -1st July 2020 (see below).

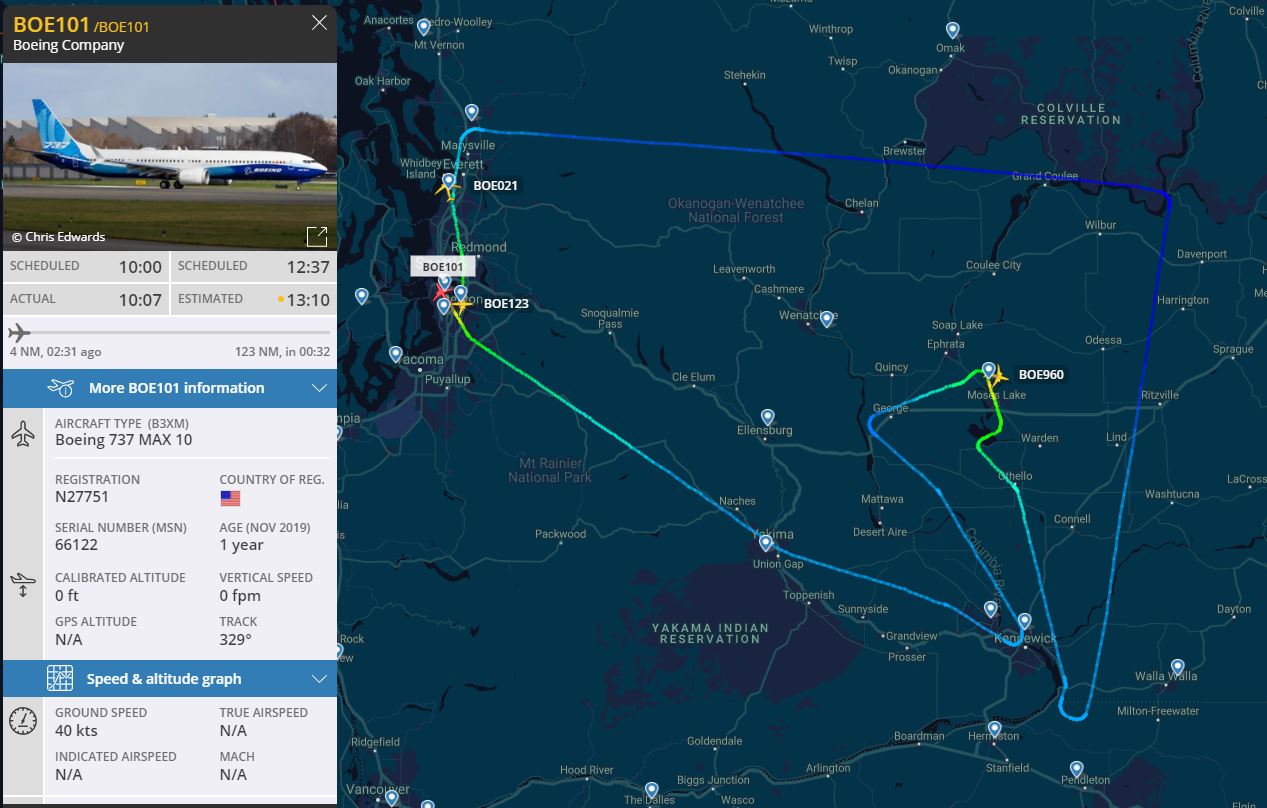

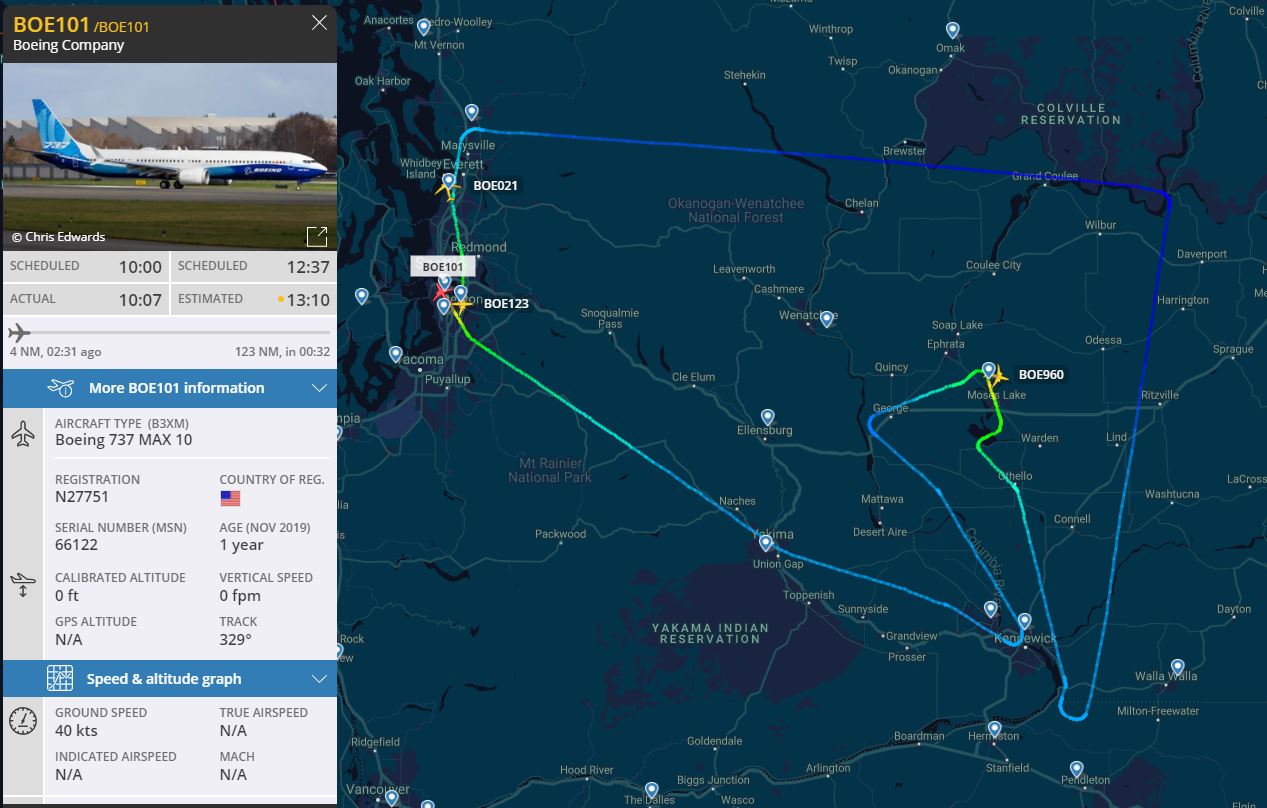

1G001. FF 18 Jun 2021, Boeing livery, N27751, MSN 66122, LN 7644, MAX-10

1G001, has been flying consistently throughout 2025 and has accumulated almost 1,100 flight hours over 319 flights since its first flight in June 2021.

1G002. FF ?, Boeing livery, N27752, MSN 66123, LN 7705, MAX-10

1G002 has accumulated 424 hours over 150 flights.

1G003. FF ?, Boeing livery, N27753, MSN 66118, LN 7935, MAX-10

This airframe resumed flight tests on 6 Oct 2025, having last flown in early August 2025. Test aircraft 1G003 now has 253 hours over 80 flights.

The first flight was 18 Jun 2021 at 10:07am PDT (18:07 GMT) from Renton to Boeing Field via a touch and go at Moses Lake. The airframe was N27751 (66122/7644) which was conducting taxy trials on 16 Jun.

In command was 737 Chief Pilot Jennifer Henderson and Boeing Test and Evaluation Chief Pilot Jim Webb as co-pilot. The aircraft used callsign Boeing 101 (Ten one). After departure it turned East climbing up to 23,000ft for basic handling checks. It then turned South and descended to 15,000 ft for low speed handling tests. There was then a touch and go at Moses Lake before returning to Boeing Field at 12:38 p.m. local time.

Boeing 737 chief pilot Captain Jennifer Henderson said, “The airplane performed beautifully. The profile we flew allowed us to test the airplane’s systems, flight controls and handling qualities, all of which checked out exactly as we expected.”

As of 23 Aug 2022, the initial pair of 737-10 development aircraft had amassed some 730 flight hours on around 245 flights, of which the bulk have been accumulated by the first aircraft, 1G001. As well as evaluations of stability, control and overall handling, test work has focused on areas affected by the new design aspects of the stretched aircraft such as runway performance, braking, autoflight system checks and crosswind performance. Initial takeoff performance tests conducted at Edwards AFB, California, at the end of February included minimum liftoff speeds, rotation rates, takeoff distances and tail contact margins. Boeing says this initial phase, which demonstrated that the 737-10 configuration will satisfy certification performance requirements and help determine takeoff performance parameters for the flight manual, was successfully completed. “The second phase is certification testing, and that will be conducted at a later date with the regulators,” it adds. The third test aircraft “has already been in ground testing, and we intend to introduce it into flight testing later this year,” says Boeing. Configured with a full cabin, the aircraft will be used for interior systems checks including environmental control system work—augmenting similar checks already underway with the first two aircraft. As of late August, 1G001 was being used to conduct inlet temperature evaluations while 1G002 was undertaking smoke penetration tests of the cargo compartment—work traditionally done toward the tail end of the test campaign.

After over 1,000 hours or experimantal flight testing, certification flight testing with the FAA began 22 Nov 2023. Certification is expected late 2024 or early 2025.

Other tests:

Now flying with CFM Leap-1B compliance engines, airplanes two, three and four will eventually get fitted with final delivery engines that have new low-pressure compressors (LPC). Those engines, which Teal said would start arriving around August 2016, will require what he characterized as some minor additional testing. Last year CFM discovered the need to modify the LPC to improve stall margin. With the original engines, Boeing has to use suboptimum bleed schedules, leaving the bleeds open more than desired for the best possible fuel efficiency. “We want the bleeds closed for better fuel mileage,” explained Teal. “We could have certified and delivered these engines, but we wanted the best engines. So in the ones we’re flying now the bleeds are opened a little bit more than we desire, but when the final Block 2s come in and we get the final bleed schedules, and that will determine the final configuration.”

Further evaluations will be conducted late in the program on the delivery-standard Leap 1B engine with an improved low-pressure (LP) compressor configuration. The current fleet is powered by compliance versions of the -1B engine, and Boeing expects to receive the upgraded powerplants, “in the August time frame,” says Teal. “We plan on putting them on Aircraft Two, Three and Four. We won’t put them on Aircraft One because that airplane essentially [will be] done with its [test] life.” Testing will include natural icing and other minor evaluations, he adds. Improvements were made to the LP compressor after testing indicated it was necessary for bleed valves to remain open for longer than expected to maintain adequate stall margin. “They didn’t have to be open all the time. The bleed schedules open and close the valves, so to improve stall margin, we want the bleeds closed for better fuel mileage,” Teal explains. “CFM could have certified the existing engines, and they did, but we wanted the best engines. The bleeds are open a little more than desired on the engines that are flying now, but when the final Block 2s come in, we will get the final bleed schedules that will determine the final configuration.”

MCAS Flight Testing

14 March 2019 the 737 MAX was grounded following two accidents in which the MCAS system was implicated. As part of the recertification a flight test program was undertaken with the redesigned MCAS system. The program would comprise 1300 test flights.

16 Apr 2019 the MCAS flight test program concluded after 120 flights / 203 hours flight test time. The Boeing CEO, Dennis Muilenburg flew on a 737 Max demonstration flight, where he “saw first-hand this software in its final form, operating as designed across a range of flight conditions”.

15 May 2019 Boeing completed development of the software update, simulator testing and engineering test flights for the 737 MAX. In a statement, the company said that it has flown the updated software on the 737 MAX for more than 360 hours on 207 flights. “We are now providing additional information to address the Federal Aviation Administration (FAA) requests that include additional detail on how pilots interact with the airplane controls and displays in different flight scenarios,” the statement said. “Once the requests are addressed, we will work with the FAA to schedule their certification test flight and submit final certification documentation.”

5 Aug 2019 the Boeing CEO, Dennis Muilenburg said that the MAX has conducted almost 500 test flights with the new FCC software. Muilenburg said that he has personally flown on two of the test flights, and that Boeing employees are “eager to do the same.”

A MAX MCAS flight test. Note the airspeed and offshore location, clearly indicating low speed flight testing

The above graphic shows a 737 MAX 7 that took off from King County International Airport-Boeing Field near Seattle. It climbed to 24,000 feet as it headed west to the Pacific Ocean, then due south. The aircraft then descended to 13,000 feet and 250kts, about 50 miles off the Oregon coast. The aircraft then operated for almost two hours in the block between 10,000 to 14,000ft at speeds of between 130 and 300kts before climbing to recover back to Boeing Field.

The pilots of the test flights, Boeing revealed, are Jennifer Henderson and Jim Webb. Henderson, a former engineer and U.S. Air Force pilot, is the chief pilot for 737s at Boeing, who has also served Boeing as the flight test director for the 787 Dreamliner and the chief test pilot for the 737 MAX-7 during her 14 years with the company. Webb, Boeing's chief pilot for commercial airplanes, is a former U.S. Navy test pilot who as recently as last year held Henderson's role as chief 737 pilot. “Of course the expectation is we know how to fly the airplanes and are experts in the systems. We also have to have an awareness of how the manufacturing system works, how the testing goes from beginning to end, the business aspects and the direct link between our customers and our products," said Webb. Both Henderson and Webb were required to sign off on the 737 MAX's new system before it was allowed to take to the air.

29 Jun 2020 at 17:53GMT MAX 7 N7201S flew from Boeing Field to Moses Lake, landed for about 15 minutes and returned back to BFI at 22:14Z. The flight tests were part of a 3-day certification flight test program with pilots from the FAA focused on MCAS activation. Traces from Plane Finder show the aircraft manouvering to the East of Moses Lake the aircraft maintains 14,000ft and decellerates from 195Kts to 136Kts during which time it descends to 12,900ft before recovering back to 14,000ft. Such manouvres suggest stalling.

1 July 2020 - The FAA and Boeing today completed the certification flight tests on the Boeing 737 MAX. During three days of testing this week, FAA pilots and engineers evaluated Boeing’s proposed changes in connection with the automated flight control system on the aircraft. While completion of the flights is an important milestone, a number of key tasks remain, including evaluating the data gathered during these flights. The agency is following a deliberate process and will take the time it needs to thoroughly review Boeing’s work. We will lift the grounding order only after FAA safety experts are satisfied that the aircraft meets certification standards.

The Flightdeck during one of the MAX certification test flights with the FAA (Photo FAA)

6 April 2020 - Start of Operational Readiness Review, This is a series of test flights over the next several weeks featuring FAA pilots along with airline crews from around the world, all intended to vet changes to the fleet's flight-control system.

26 Aug 2020 - Transport Canada has successfully completed a series of flight test activities of the updated aircraft as part of the validation process. From August 23 to 25, 2020, Transport Canada’s flight test crew were flown to Seattle, Washington, to conduct evaluations on the engineering simulator at the Boeing facility and then at the end of the each test day, were flown back to Vancouver.

The flight test evaluations took place on August 26 and 27 in U.S. airspace using the Boeing test aircraft. Mitigation measures due to the COVID-19 pandemic were established for the validation activities, including the flight tests, to ensure the health and safety of Transport Canada employees.

Canada is the first international regulator to complete validation testing activities of the aircraft. Transport Canada is now analyzing the results of these tests. Transport Canada will determine, through its own independent review, whether to validate the proposed changes. This fall, once our analysis is completed, Transport Canada will participate in a Joint Operational Evaluation Board, which is made up of representatives from global certification authorities. The results of the Board will be used to establish the minimum training requirements for the return to service of the 737 MAX 8 aircraft.

10 Sep 2020 - European Union Aviation Safety Agency (EASA) conducted a single flight test in Vancouver, Canada using aircraft 737-7 1E001. The flight lasted 2hr 27min. EASA said “While Boeing still has some final actions to close off, EASA judges the overall maturity of the re-design process is now sufficient to proceed to flight tests,”. Simulator tests were conducted in advance of the flights at a facility at London Gatwick from 1st September 2020.

16 Sep 2020 - Boeing stated that: “The revised design of the MAX has received intensive internal and regulatory review, including more than 375,000 engineering and test hours and 1,300 test flights,”

30 Sep 2020 - FAA Chief Steve Dickson and Deputy Administrator Dan Elwell personally conducted a 2 hour evaluation flight at the controls of a Boeing 737 MAX on 30 Sep 2020. Dickson has repeatedly said he would not sign off the MAX until he flew it himself and was “satisfied that I would put my own family on it without a second thought.”. The flight by Dickson will fulfill “his promise to fly the aircraft before the FAA approves its return to service.”

After the flight Dickson said “I like what I saw on the flight. We are not to the point yet where we have completed the process,” |  737 MAX Flight Test News

737 MAX Flight Test News