"AD 2019-22-10 - The FAA is superseding Airworthiness Directive (AD) 2019-20-02, which applied to all The Boeing Company Model 737-600, -700, -700C, -800, -900, and -900ER series airplanes. AD 2019-20-02 required repetitive inspections for cracking of the left- and right-hand side outboard chords of frame fittings and failsafe straps at a certain station around two fasteners, and repair if any cracking is found. This AD also requires repetitive inspections for cracking of the left- and right-hand side outboard chords of frame fittings and failsafe straps at a certain station, but expands the inspection to the area around eight fasteners, and also requires repair if any cracking is found. This AD was prompted by a determination that the inspection area needs to be expanded. The FAA is issuing this AD to address the unsafe condition on these products."

Aircraft with more than 30,000 cycles must be inspected within seven days, while aircraft between 22,600 and 29,999 cycles must be inspected within 1,000 cycles.

By 10 Oct 2019, 38 out of 810 aircraft inspected (about 5%) had been found to have cracks. It should be noted that inspections have mainly been focused on the oldest aircraft, so the percentage of aircraft with cracks found should reduce as newer aircraft are inspected. By 30 Oct 2019, 50 aircraft had been found with cracks.

Boeing is setting up a repair station in Victorville, California, and expects fixes to take two to three weeks per aircraft.

It is not yet clear why the pickle forks developed cracks. When aircraft parts fail, investigators examine whether there could have been a problem with design, materials, or the manufacturing process. The FAA said it was working with international safety regulators to understand what caused the cracks to form. Current theories include the addition of winglets which have changed the wing loading since the original design of the NG; the cumulative effect of heavy landings or a manufacturing fault.

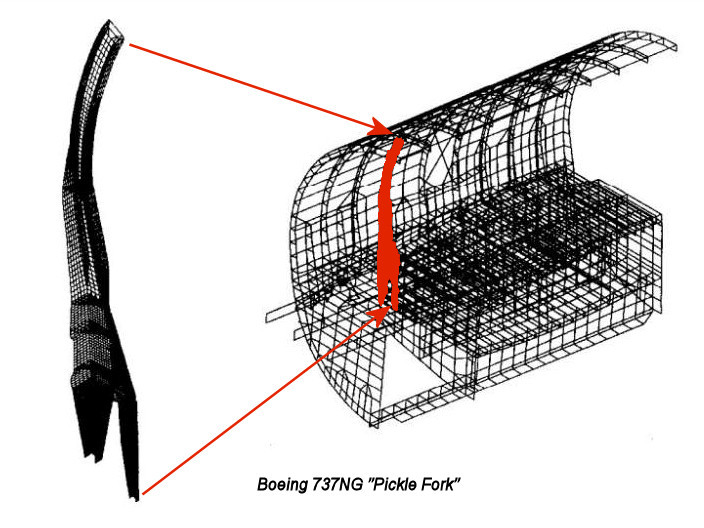

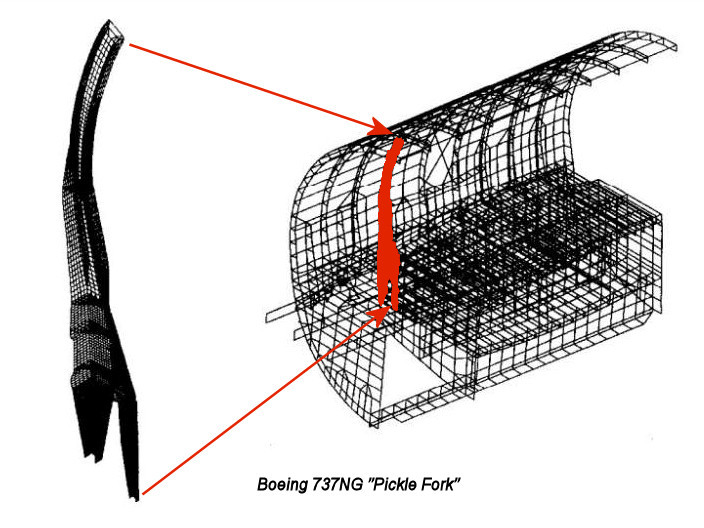

The Pickle Fork

Photograph of a pickle fork in situ (photo Yonhap News)

Photograph of a pickle fork crack (photo internet source unknown)

More details from AD 2019-20-02

Discussion

In September 2019, the FAA received reports of cracking discovered in the left and right hand side outboard chords of the station (STA) 663.75 frame fittings and failsafe straps adjacent to the stringer S-18A straps on multiple Boeing Model 737-800 airplanes during a passenger-to-freighter conversion. The affected airplanes had accumulated between 35,578 and 37,329 total flight cycles. Cracking in the STA 663.75 frame fitting outboard chords and failsafe straps adjacent to the stringer S-18A straps, if not addressed, could result in failure of a Principal Structural Element (PSE) to sustain limit load. This condition could adversely affect the structural integrity of the airplane and result in loss of control of the airplane.

Related Service Information Under 1 CFR Part 51

The FAA reviewed Boeing Multi-Operator Message MOM-MOM-19-0536-01B, dated September 30, 2019. This service information describes procedures for a detailed inspection for cracking of the left and right hand side outboard chords of the STA 663.75 frame fittings and failsafe straps adjacent to the stringer S-18A straps. This service information also provides procedures for reporting inspection results to Boeing. This service information is reasonably available because the interested parties have access to it through their normal course of business or by the means identified in the ADDRESSES section.

FAA's Determination

The FAA is issuing this AD because the agency evaluated all the relevant information and determined the unsafe condition described previously is likely to exist or develop in other products of the same type design.

AD Requirements

This AD requires repetitive inspections for cracking of the left and right hand side outboard chords of the STA 663.75 frame fittings and failsafe straps adjacent to the stringer S-18A straps. This AD also requires repair of all cracking using a method approved by the FAA or The Boeing Company Organization Designation Authorization (ODA). This AD also requires sending a report of all results of the initial inspection to Boeing.

Interim Action

The FAA considers this AD interim action. The inspection reports that are required by this AD will enable the manufacturer to obtain better insight into the nature, cause, and extent of the cracking, and eventually to develop final action to address the unsafe condition. Once final action has been identified, the FAA might consider further rulemaking.

|

737NG Pickle Fork ADs

737NG Pickle Fork ADs