The three marks on the fuselage indicate the upper, neutral and lower limit of travel of the horizontal stabilizer.

FCTM Dsicussion on Runaway Stabiliser

The FCTM has been updated since the MAX return to service review in 2020 as follows:

"A runaway stabilizer condition can be recognized by continuous uncommanded movement of stabilizer trim, or if stabilizer trim is occurring in a manner that is not appropriate for current flight conditions. During manual flight or flight with the autopilot engaged, automatic stabilizer trim can be commanded by the Speed Trim System or autopilot trim. Since commanded stabilizer trim can occur automatically, the pilot needs to consider the existing flight conditions to determine if a runaway stabilizer condition exists. For example, some stabilizer trim movement can be expected to occur during speed, altitude, or configuration changes."

"During a runaway stabilizer condition the crew should maintain airplane pitch control through the use of the control column, main electric stabilizer trim, and thrust levers. The control column must be held firmly before the autopilot (if engaged) is disengaged to maintain airplane pitch control and retain any elevator commands from the autopilot. After the autopilot and autothrottle are disengaged, use the control column and thrust levers to establish appropriate pitch attitude and airspeed. If uncommanded trim motion continues, it may stop when the control column is displaced in the opposite direction and the control column cutout is activated. Use main electric stabilizer trim to reverse any stabilizer trim movement and to reduce control column forces. Sustained use of main electric stabilizer trim may be needed. It is important to note that even though the steps in the Runaway Stabilizer checklist are sequential, these steps can be accomplished simultaneously. If uncommanded stabilizer trim movement continues, place both STAB TRIM cutout switches to the CUTOUT position. Manual stabilizer trim should then be used for the remainder of the flight."

The evolution of the QRH Procedure

1967-1987

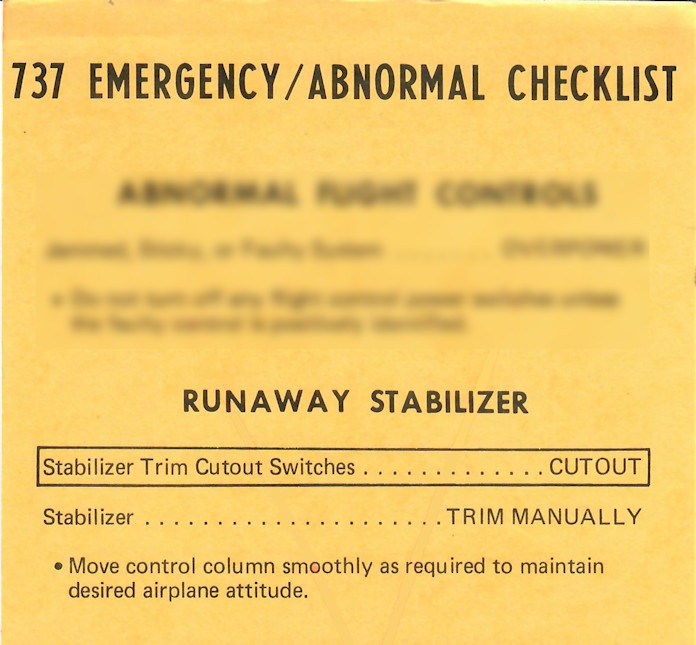

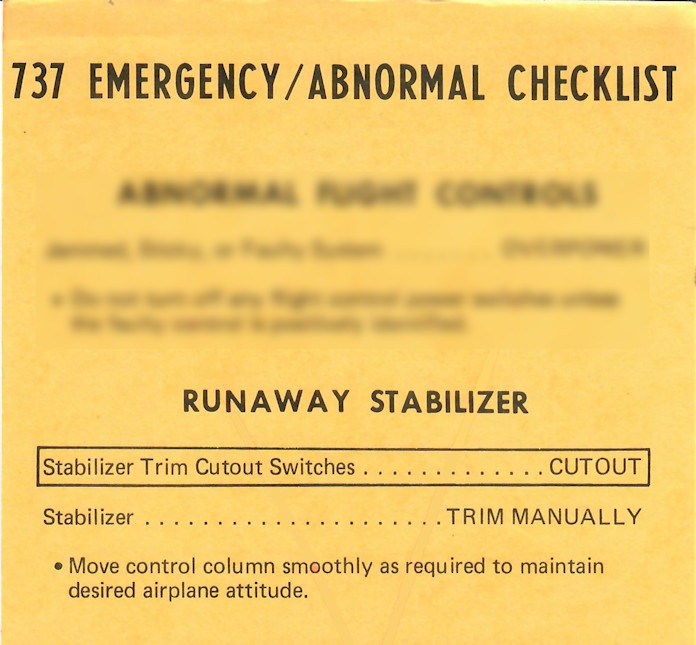

The whole procedure is just 3 lines long!

One memory item: “Stab Trim Cutout Switches____CUTOUT”

One Non-memory item: “Stabilizer __________ Trim manually”

And one note: Move control column smoothly as required to maintain desired airplane attitude.

Above left: QRH from 1975; Above right Stab trim cutout switches in a 737-200. They kept the same function until the MAX.

.

1987-2000

After 20 years Boeing added a second memory item: “If runaway trim continues: Stabilizer Trim Wheel ______ Grasp and hold” and some helpful notes.

Above: QRH from 1987

Above: Classic stab trim cut-out switches

2000-2013

By the year 2000, the procedure had expanded to 4 memory items:

Above: QRH from 2000

.

2013-2018

In 2013 the procedure changed to add in the step of disengaging the Autothrottle, and ending the procedure if disengaging the A/P stopped the runaway trim, taking it up to 5 memory items:

There are then 2 more non-memory items and a page of deferred items making a total of two full QRH pages, quite a difference from the 1967 3-liner!

2018-2020

Following the Lion Air accident, on 7 Nov 2018 the FAA issue an Emergency AD (2018-23-51) and Boeing issue an Ops Manual Bulletin (TBC-19) for MAX Runaway Stabilizer procedure directing operators to “existing flight crew procedures" to address circumstances involving erroneous angle-of-attack sensor information.

FAA Emergency AD 2018-23-51 - SUMMARY: We are adopting a new airworthiness directive (AD) for all The Boeing Company Model 737-8 and -9 airplanes. This emergency AD was sent previously to all known U.S. owners and operators of these airplanes. This AD requires revising certificate limitations and operating procedures of the airplane flight manual (AFM) to provide the flight crew with runaway horizontal stabilizer trim procedures to follow under certain conditions. This AD was prompted by analysis performed by the manufacturer showing that if an erroneously high single angle of attack (AOA) sensor input is received by the flight control system, there is a potential for repeated nose-down trim commands of the horizontal stabilizer. We are issuing this AD to address the unsafe condition on these products..

This AD requires revising certificate limitations and operating procedures of the airplane flight manual (AFM) to provide the flight crew with runaway horizontal stabilizer trim procedures to follow under certain conditions.

2020-Current

On 18 Nov 2020 the FAA issued AD 2020-24-02 requiring several 737 MAX design and QRH changes as part of the ungrounding order. This included a change to the Runaway Stabiliser procedure as follows:

A key difference to the previous procedure is the recognition criteria have changed from a "continuous" uncommanded movement to "continuously or in a manner not appropriate for flight conditions".

The changes are discussed at length on page 16 of the AD which I have reproduced below:

The following summarizes the comments received on the NPRM, and provides the FAA's responses.

F. Suggestions for Crew Procedure Changes

1. Comments Regarding AFM Crew Procedure Adequacy

Comment summary: Several commenters, including BALPA, NATCA, ALPA, Boeing, the Allied Pilots Association, the JEMOG, Ethiopian Airlines Group, A4A, and SWAPA, requested that

the FAA modify the emergency and non-normal procedures contained in the proposed AD. These comments covered several of the proposed checklists, with an emphasis on the Airspeed Unreliable and Runaway Stabilizer checklists. The comments included requests to make small changes involving typographical errors, to add information to checklists, to simplify checklists, to shorten or reduce the number of memory items, and to develop checklists for certain specific failure cases. Three commenters, including BALPA and Ethiopian Airlines Group, recommended providing a combined Airspeed Unreliable and Runaway Stabilizer checklist for certain specific failure conditions.

...

FAA response: The FAA has made several changes to the checklists, taking into consideration not only comments provided in the context of the NPRM, but also in response to the outcomes from the FAA FSB evaluation. The inputs from the FAA FSB were the result of collaboration with other CAAs during the JOEB. The JOEB conducted an extensive evaluation of the proposed procedures and training conducted by a wide variety of crews, including line pilots with levels of experience ranging from high to low and regulatory pilots from four separate CAAs during the NPRM comment period.

The AFM procedures specified in the proposed AD were the result of procedural development conducted by FAA test pilots, human factors, and operations personnel (along with other engineering and operational experts from other CAAs and from Boeing), which considered a myriad of similar aspects as the procedures were developed and evaluated. Additionally, the procedures were evaluated during FAA certification, including human factors evaluations to determine compliance to 14 CFR 25.1302, and system safety assessments to determine compliance to 14 CFR 25.1309. The FAA convened a team of test pilots, operational pilots, and human factors experts during the development of the AFM procedures specified in the proposed AD. The FAA convened a similar team to consider each procedural comment made during the NPRM comment period and to determine if changes were warranted to improve safety.

A4A and SWAPA expressed concern that there are too many recall items in the Runaway Stabilizer non-normal procedure, and included a suggestion for how to reduce the number of steps. The suggestion included combining some recall items to achieve fewer numbered steps, but with multiple embedded actions in each recall item, such that the suggested changes would result in the same number of required flightcrew actions. The FAA agrees that it is desirable to minimize recall items when appropriate. The recall steps in the non-normal procedures required by paragraph (h) of this AD reflect flightcrew actions required to address a runaway stabilizer condition. Based on the FAA's evaluation and in coordination with human factors specialists, the FAA determined that the commenters' proposed changes would complicate the recall steps and would increase the likelihood that a critical flightcrew action is forgotten or missed. The FAA considered all of the commenters' requests in the context of crew workload, clarity of instruction, consistency with training objectives, and consistency with other procedures contained in the AFM. The FAA declines the request to combine checklists because checklists must be applicable to all potential failure conditions, not just the specific failure conditions noted by the commenters. Additionally, the failure conditions where a combined checklist might be useful were evaluated by multiple flightcrews, resulting in a conclusion by the FAA that, primarily due to the new MCAS required by this AD, the order and content in which these two checklists were accomplished is not critical to continued safe flight and landing.

Above: NG stab trim cut-out switches

Dennis Tajer of the Allied Pilots Association, which represents 15,000 pilots of American Airlines, has said of the FAA review: "I want them to be invasive. I want them to be aggressive. I want them to be obstinate about knowing all of the information, I want them to be more than trust but verify." He went on to say that even if the basic steps do not change, the spartan checklist language could be augmented with instructions such as those contained in Boeing supplemental materials: "It may take two pilots to manually trim the aircraft." "It may require elevator load alleviation in order to manually trim the aircraft." I have to say that I agree that more information in the QRH would be helpful.

US government officials told The Wall Street Journal in late May that the FAA is evaluating the emergency procedures not only for the Max, but also for older generations of the 737 including the NG. A Boeing spokesman responded in a statement "While we are working with the FAA to review all procedures, the safety of the 737 NG is not in question, with its 20-plus years of service and 200 million flight hours."

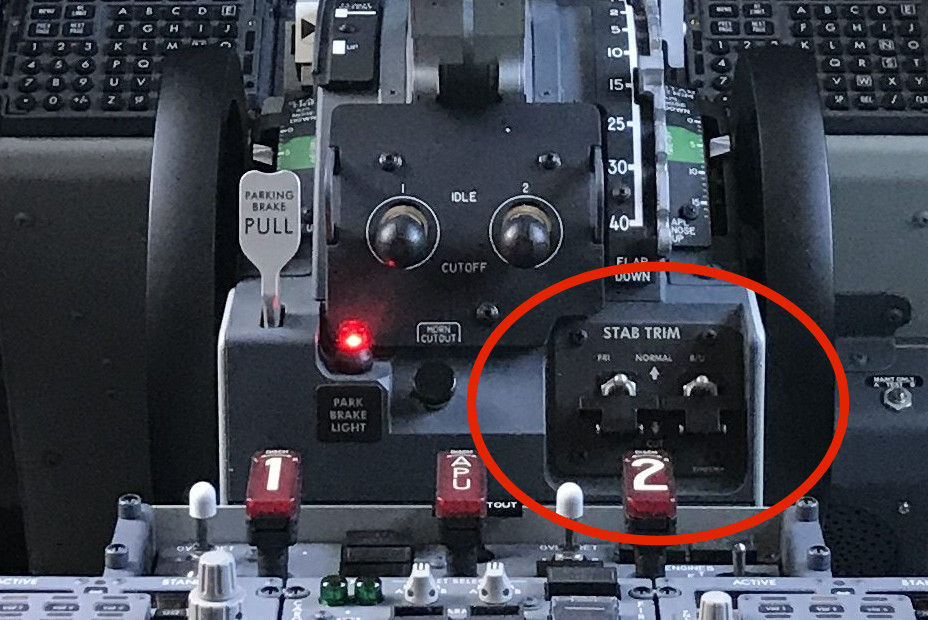

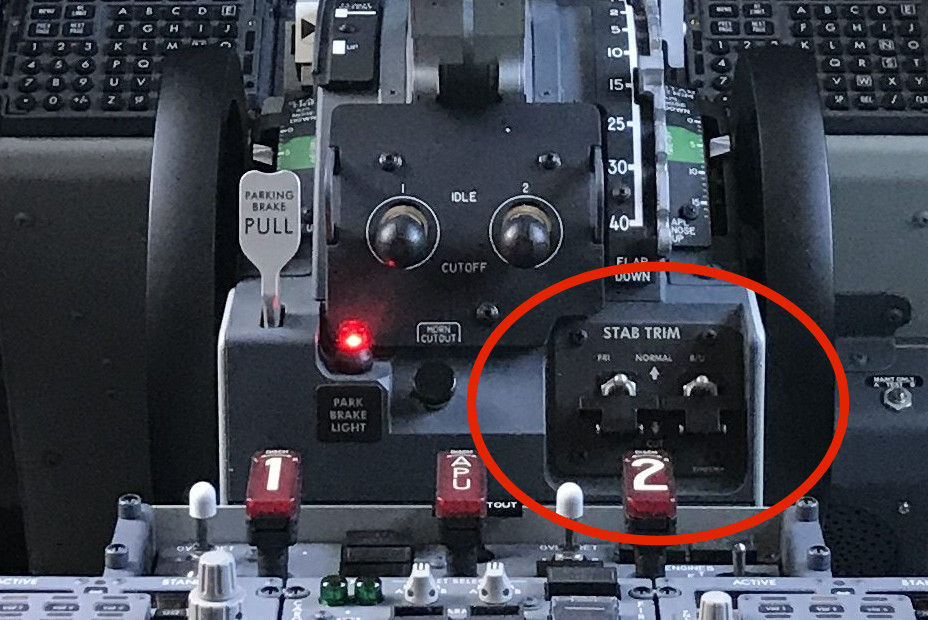

MAX Differences

Note that on the MAX, the MAIN ELEC and AUTO PILOT Stab trim switches now either switch will cut-off both main electric and autopilot stab trim. They are renamed PRI and B/U (primary and backup). The switches are guarded in the NORMAL position (switch up) and CUTOFF is switch down. The QRH procedure is the same for all 737s.

Above: MAX stab trim cut-out switches

The "Roller Coaster" Manouvre

The current FCTM states:

Manual Stabilizer Trim

If manual stabilizer trim is necessary, ensure both stabilizer trim cutout switches are in CUTOUT prior to extending the manual trim wheel handles.

Excessive airloads on the stabilizer may require effort by both pilots to correct the mis-trim. In extreme cases it may be necessary to aerodynamically relieve the airloads to allow manual trimming. Accelerate or decelerate towards the in-trim speed while attempting to trim manually. [This is known as the "roller coaster" or "yo-yo" manoeuvre!]

Anticipate the trim changes required for the approach. Configure the airplane early in the approach. When reaching the landing configuration, maintain as constant a trim setting as possible. If a go-around is required, anticipate the trim changes as airspeed increases.

The FCT 737 (PTM) c1982 described the "roller coaster" manouvre in better detail as follows:

Recovery from a Severe Out of Trim

Accelerate or decelerate the airplane to an in-trim airspeed. If a recovery must be initiated from an extreme nose-down out-of-trim requiring a high pull force, an increase in airspeed may relieve enough of the elevator load and control displacement to permit manual trimming. Do not exceed speeed limitation. If a recovery must be initiated from an extreme nose-up out-of-trim requiring a high push force, a decrease in airspeed may relieve enough of the elevator load and control displacement to permit manual trimming. It should be noted that the relationship between airspeed change and trim change do not remain constant. As airspeed is increased, trim change requirements decrease.

In an extreme nose-up out-of-trim condition, requiring almost full forward column, decellerate, extend the flaps and/or reduce thrust to a minimum practical setting consistent with flight conditions until elevator control is established. Do not decrease airspeed below the minimum manouvring speed for the flap configuration. A bank of 30 degrees or more will relieve some force on the control column. This, combined with flap extension and reduced speed, should permit easier manual trimming.

If other methods fail to relieve the elevator load and control column force, use the "roller coaster" technique. If nose-up trim is required, raise the nose well above the horizon with elevator control. Then slowly relax the control column pressure and manually trim nose-up. Allow the nose to drop below the horizon while trimming. Repeat this sequence until the airplane is trim. If nose-down trim is required, slowing down and extending the flaps will account for a large degree of nose-up pitch. If this does not allow manual trimming then the reverse "roller coaster" can be performed to permit manual trimming.

This operation is analagous to reeling in a big fish where the line is kept taught by keeping the pole-tip bent. Then, to reel in, the pole is dipped quickly while cranking fast to keep a pull on the line.

Flight crews should not hesitate to apply whatever force is necessary on the trim handwheel because the system is designed for large handwheel loads.

Airliner Magazine, May 1961 gives more details. It is based on the 707 but the system and technique are the same. |

Runaway Stabilizer Procedure

Runaway Stabilizer Procedure